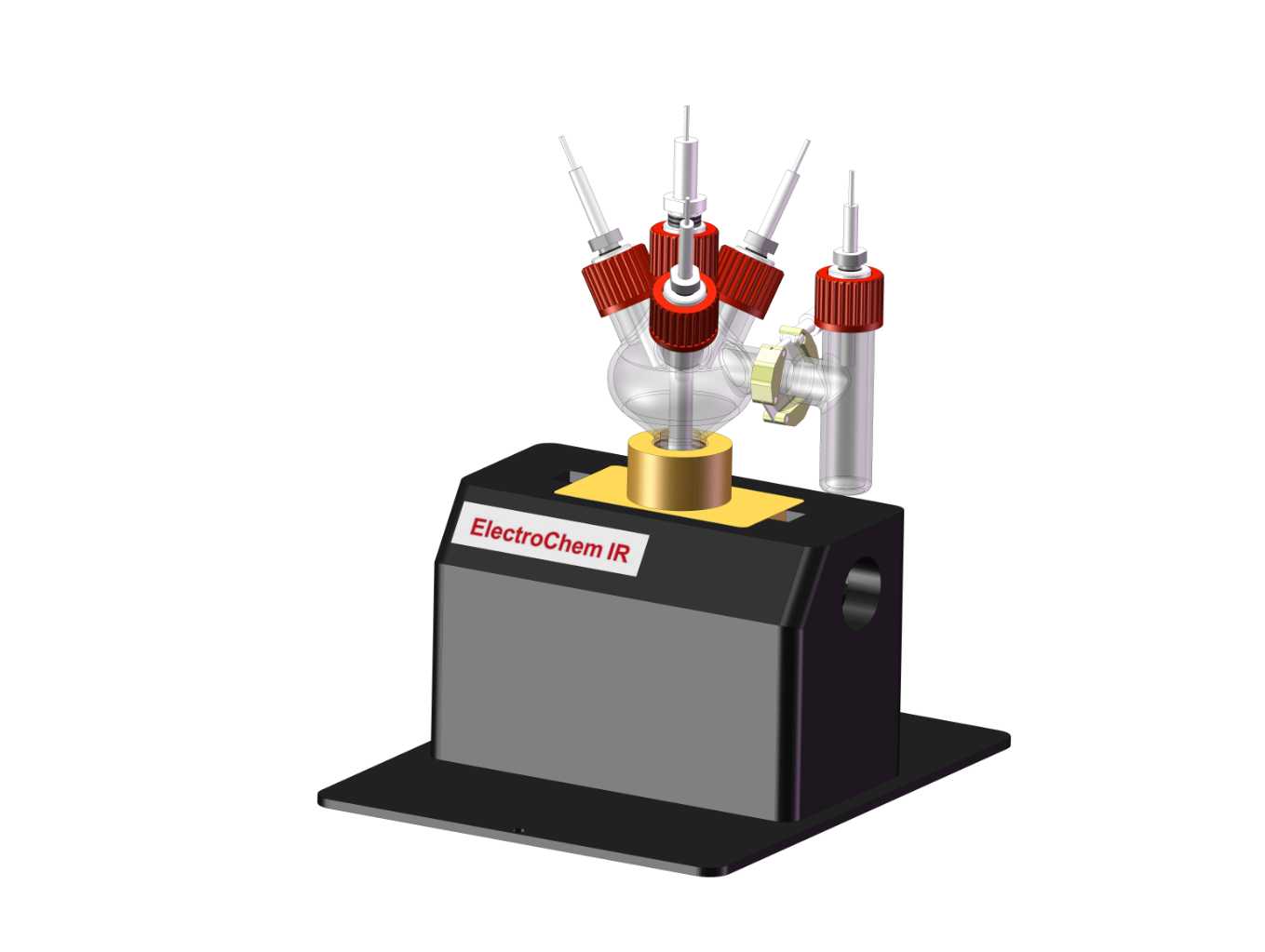

电催化原位红外附件

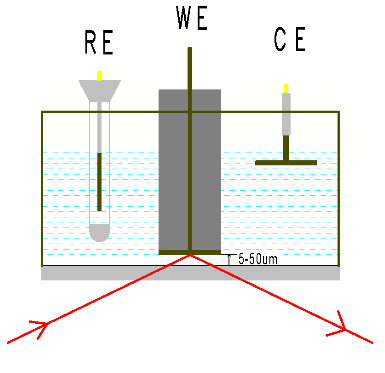

图1:原理示意图

电化学原位红外光谱分析是红外分析技术的一个重要分支,能够定性分析电催化(如CO2电还原等)反应、各种类型电池(如锂离子、锂硫电池等)充放电过程中电极表面的产物或中间产物随时间(电位)不断变化的趋势,是研究电化学反应机理以及电化学反应动力学的重要手段之一。

一 基本原理:

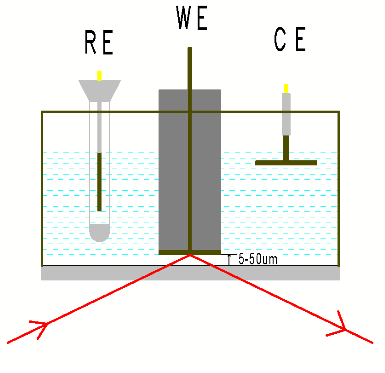

内反射模式:

(1)在单晶硅(Si)上化学镀或真空镀一层纳米金膜,纳米金属膜具有表面增强效应。

(2)纳米金膜可作为导电基底,在导电基底上滴涂或电沉积上电催化剂,作为工作电极。

(3)表面增强红外,可得到电催化剂吸附态产物以及中间产物信息。

图2:内反射模式基本原理

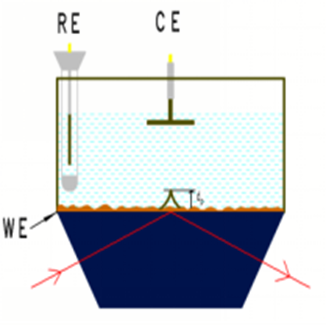

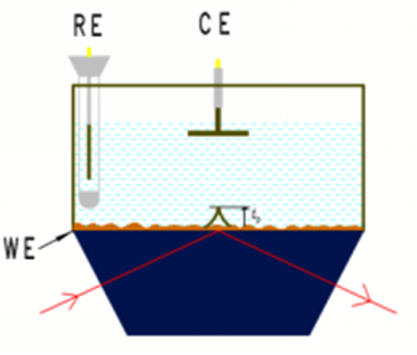

外反射模式:

(1)在基底电极(如GCE)表面电沉积或滴涂电催化剂作为工作电极。

(2)工作电极距离晶体的距离可以调节。

(3)晶体可选Ge,ZnSe,CaF2,Si等。

图3:外反射模式基本原理

二 附件组成:

(1)红外光谱仪主机适配底板,适配主流红外光谱仪。

(2)平面镜加曲面镜。

(3)入射角度调节系统。

(4)衰减全反射晶体。

(5)玻璃电化学池(单池或H型池)以及PEEK外反射池。

(6)电极(玻碳电极、对电极、参比电极)。

(7)距离调节系统。

三 主要特点:

(1)可变入射角光学台,30-80度连续可调,以保证不同电催化剂处于最大光通量状态。

(2)衰减全反射晶体上具有一层增透膜,光通量增大10%以上

(3)电化学池密封性能好,可通入反应气体。

(4)晶体拆卸简单,方便打磨清洗。

(5)晶体种类可选,如Si,CaF2,ZnSe等。

(6)电化学单池或H型池,切换方便。

(7)提供现场技术服务。

(7)可根据客户需求定制反应池并提供可行性方案。

四 ATR Crystal characteristics for FTIR sampling

Crystal | pH range | Spectrum range(cm-1) |

Diamond | 1-14 | 250/525-4000 |

Ge | 1-14 | 575-5000 |

Silicon | 1-12 | 1200-8900 |

ZnSe | 5-9 | 525-15000 |

CaF2 | 5-8 | 1100-7700 |

应用案例

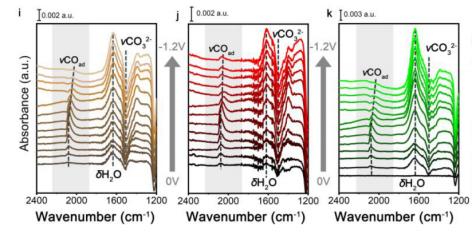

CO2电还原 J. Am. Chem. Soc.2022, 144, 259−269

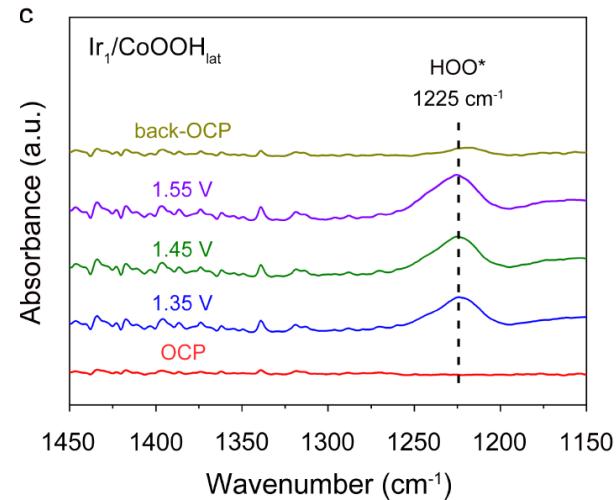

氧气析出反应 J. Am. Chem. Soc. 2022, 144, 21, 9271–9279

部分客户论文发表清单:

Jianping Xiao*, Bin Zhang*, et al. Unveiling hydrocerussite as an electrochemically stable active phase for efficient carbon dioxide electroreduction to formate. Nat. Commun. 2020, 11, 3415

Lei Yan, Yonggang Wang*, et al. Chemically Self-Charging Aqueous Zinc-Organic Battery. J. Am. Chem. Soc. 2021, 143, 15369-15377

Bingliang Wang, Yongyao Xia*, et al. In situ structural evolution of the multi-site alloy electrocatalyst to manipulate the intermediate for enhanced water oxidation reaction. Energy Environ. Sci. 2020, 13, 2200-2208

Yang Peng*, et al. Breaking Linear Scaling Relationship by Compositional and Structural Crafting of Ternary Cu-Au/Ag Nanoframes for Electrocatalytic Ethylene Production. Angew. Chem. Int. Ed. 2021, 60, 2508-2518

Zhuo Yu, Yonggang Wang*, et al. Boosting Polysulfide Redox Kinetics by Graphene-Supported Ni Nanoparticles with Carbon Coating. Adv. Energy Mater. 2020, 10, 2000907

Xinwei Ding, Zhi Yang*, et al. Biomimetic Molecule Catalysts to Promote the Conversion of Polysulfides for Advanced Lithium–Sulfur Batteries Adv. Funct. Mater. 2020, 30, 2003354

Hong Guo*, Xueliang Sun*, et al. Dual Active Site of the Azo and Carbonyl-Modified Covalent Organic Framework for High-Performance Li Storage. ACS Energy Lett. 2020, 5, 1022-1031

Bin Zhang* et al. Superficial Hydroxyl and Amino Groups Synergistically Active Polymeric Carbon Nitride for CO2 Electroreduction. ACS Catal. 2019, 9, 10983-10989

Suya Zhou, Zhi Yang*, et al. Dual-Regulation Strategy to Improve Anchoring and Conversion of Polysulfides in Lithium–Sulfur Batteries ACS Nano. 2020, 14, 7538–7551

Yongyao Xia*, et al. Low-Temperature Charge/Discharge of Rechargeable Battery Realized by Intercalation Pseudocapacitive Behavior. Adv. Sci. 2020, 7, 2000196

Lei Wang*, Yonggang Wang, et al. Pencil-drawing on nitrogen and sulfur co-doped carbon paper: An effective and stable host to pre-store Li for high-performance lithium–air batteries. Energy Storage Materials. 2020, 26, 593-603

Bin Zhang, et al. Unveiling in situ evolved In/In2O3− x heterostructure as the active phase of In2O3 toward efficient electroreduction of CO2 to formate. Science Bulletin. 2020, 65, 1547-1554

Huani Li, Shubiao Xia*, Hong Guo*, et al. Red Phosphorus Confined in Hierarchical Hollow Surface-Modified Co9S8 for Enhanced Sodium Storage. Sustainable Energy Fuels. 2020, 4, 2208-2219

Guanglei Cui*, Liquan Chen, et al. Non-flammable nitrile deep eutectic electrolyte enables high voltage lithium metal batteries. Chem. Mater. 2020, 32, 3405-3413

Guanglei Cui*, et al. Investigation on the Cathodic Interfacial Stability of Nitrile Electrolyte and its performance with High Voltage LiCoO2 Chem. Commun. 2020, 56, 4998-5001

Zhongbin Zhuang*, et al. A highly-active, stable and low-cost platinum-free anode catalyst based on RuNi for hydroxide exchange membrane fuel cells. Nat. Commun. 2020, 11, 5651

Tiancun Liu, Yong Wang*, et al. Organic supramolecular protective layer with rearranged and defensive Li deposition for stable and dendrite-free lithium metal anode. Energy Storage Materials. 2020, 32, 261–271

X. Yin, Y. Wang*, et al. Designing cobalt-based coordination polymers for high-performance sodium and lithium storage: from controllable synthesis to mechanism detection. Materials Today Energy. 2020, 17, 100478

Song Chen, Jintao Zhang*, et al. Regulation of Lamellar Structure of Vanadium Oxide via Polyaniline Intercalation for High-Performance Aqueous Zinc-Ion Battery. Adv. Funct. Mater. 2020, 30, 2003890

Yanrong Xue, Zhongbin Zhuang*, et al. Sulfate-Functionalized RuFeOx as Highly Efficient Oxygen Evolution Reaction Electrocatalyst in Acid. Adv. Funct. Mater. 2021, 31, 2101405

Hong Guo*, et al. Cooperative catalytic interface accelerates redox kinetics of sulfur species for high-performance Li-S batteries. Energy Storage Materials. 2021, 40, 139-149

Bin Zhang*, et al. Promoting nitric oxide electroreduction to ammonia over electron-rich Cu modulated by Ru doping. SCIENCE CHINA Chemistry. 2021, 64, 1493–1497

Yang Peng*, et al. Geometric Modulation of Local CO Flux in Ag@Cu2O Nanoreactors for Steering the CO2RR pathway toward High-Efficacy Methane Production. Adv. Mater. 2021, 33, 2101741

Yonggang Wang*, et al. Molecular Tailoring of n/p-type Phenothiazine Organic Scaffold for Zinc Batteries. Angew. Chem. Int. Ed. 2021, 60, 20826-20832

Hongliang Jiang*, Chunzhong Li*, et al. Dynamically Formed Surfactant Assembly at the Electrified Electrode–Electrolyte Interface Boosting CO2 Electroreduction. J. Am. Chem. Soc. 2022, 144, 6613–6622

Yang Peng*, et al. Au-activated N motifs in non-coherent cupric porphyrin metal organic frameworks for promoting and stabilizing ethylene production. Nat. Commun. 2022, 13, 63

Jie Zeng*, et al. Copper-catalysed exclusive CO2 to pure formic acid conversion via single-atom alloying. Nature Nanotechnology. 2021, 16, 1386-1393

Min-Rui Gao*, et al. Identification of Cu(100)/Cu(111) Interfaces as Superior Active Sites for CO Dimerization During CO2 Electroreduction. J. Am. Chem. Soc. 2022, 144, 1, 259-269

Chen Feng, Shiming Zhou*, Jie Zeng*, et al. Tuning the Electronic and Steric Interaction at the Atomic Interface for Enhanced Oxygen Evolution. J. Am. Chem. Soc. 2022, 144,21,9271-9279

Rui Lin, Jianhui Wang, et al. Asymmetric donor-acceptor moleculeregulated core-shell-solvation electrolyte for high-voltage aqueous batteries. Joule 2022, 6, 399–417

Xiaogang Zhang*, et al. Successive Cationic and Anionic (De)-Intercalation/Incorporation into an Ion-Doped Radical Conducting Polymer. Batteries & Supercaps 2019, 2, 979-984

Zhongju Wang, Yongzhu Fu*, et al. Biredox‐Ionic Anthraquinone‐Coupled Ethylviologen Composite Enables Reversible Multielectron Redox Chemistry for Li‐Organic Batteries. Adv. Sci. 2022, 9, 2103632

Jintao Zhang*, et al. Defect evolution of hierarchical SnO2 aggregatesfor boosting CO2 electrocatalytic reduction. J. Mater. Chem. A 2021, 9, 14741-14751

Fei Ai, Yijun Lu*, et al. Heteropoly acid negolytes for high-power-density aqueous redox flow batteries at low temperatures. Nature Energy 2022, 7, 417–426

Zhejun Li, Yijun Lu*. Polysulfide-based redox flow batteries with long life and low levelized cost enabled by charge-reinforced ion-selective membranes. Nature Energy 2021, 6, 517–528

Shanshan Lu, Wei Zhou. et al. Phenanthrenequinone-like moiety functionalized carbon for electrocatalytic acidic oxygen evolution. Chem. 2022, 8, 1415-1426.

Tieliang Li, Yifu Yu, Bin Zhang*, et al. Sulfate-Enabled Nitrate Synthesis from Nitrogen Electrooxidation on Rhodium Electrocatalyst. Angew. Chem. Int. Ed. 2022, e202204541

Yanbo Li, Bin Zhang, Yifu Yu*, et al. Electrocatalytic Reduction of Low-Concentration Nitric Oxide into Ammonia over Ru Nanosheets. ACS Energy Letters 2022, 7, 1187-1194

Yanmei Huang, Yifu Yu, Bin Zhang*, et al. Direct Electrosynthesis of Urea from Carbon Dioxide and Nitric Oxide. ACS Energy Letters 2022, 7, 284-291

Wenfu Xie, Hao Li, Min Wei*, et al. NiSn Atomic Pair on Integrated Electrode for Synergistic Electrocatalytic CO2 Reduction. Angew. Chem. Int. Ed. 2021, 60, 7382–7388

Rui Sui, Jiajing Pei, Zhongbin Zhuang*, et al. Engineering Ag−Nx Single-Atom Sites on Porous Concave N-Doped Carbon for Boosting CO2 Electroreduction. ACS Appl. Mater. Interfaces 2021, 13, 17736-17744

Tiliang Li, Yuting Wang, Yifu Yu*, Bin Zhang*, et al. Ru-Doped Pd Nanoparticles for Nitrogen Electrooxidation to Nitrate. ACS Catal. 2021, 11, 14032-14037

Bin Zhang*, et al. Promoting selective electroreduction of nitrates to ammonia over electron-deficient Co modulated by rectifying Schottky contacts. Science China Chemistry 2020, 63, 1469-1476

Jiangwei Shi, Bin Zhang*, et al. Promoting nitric oxide electroreduction to ammonia over electron-rich Cu modulated by Ru doping. Science China Chemistry 2021, 64, 1493-1497

Jintao Zhang* et al. Atomic Bridging Structure of Nickel-Nitrogen-Carbon for Highly Efficient Electrocatalytic Reduction of CO2. Angew. Chem.Int. Ed. 2022, 61, e20211391

Lang Xu* et al. Gadolinium Changes the Local Electron Densities of Nickel 3d Orbitals for Efficient Electrocatalytic CO2 Reduction. Angew. Chem.Int. Ed. 2022, 61, e202201166

Bin Zhang* et al. Phenanthrenequinone-like moiety functionalized carbon for electrocatalytic acidic oxygen evolution. Chem. 2022, 8, 1415-1426

Sheng Dai*, Minghui Zhua*, Yifan Han* et al. Probing the role of surface hydroxyls for Bi, Sn and In catalysts during CO2 Reduction. Applied Catalysis B: Environmental 2021, 298,

Nan Wang, Yonggang Wang*, et al. Zinc-organic Battery with a Wide Operation-temperature Window from -70 to 150 oC. Angew. Chem. Int. Ed. 2020,59,14577-14583

Nannan Meng, Yifu Yu, Bin Zhang*, et al. Efficient Electrosynthesis of Syngas with Tunable CO/H2 Ratios over ZnxCd1-xS-Amine Inorganic-Organic Hybrids. Angew. Chem. Int. Ed. 2019, 58, 18908–18912